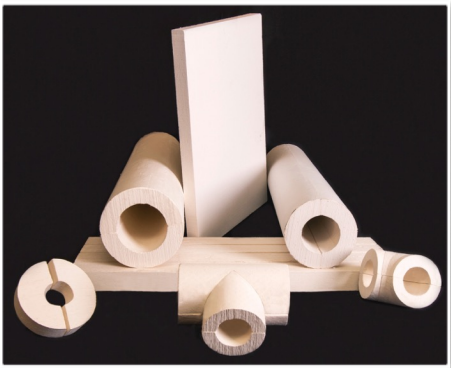

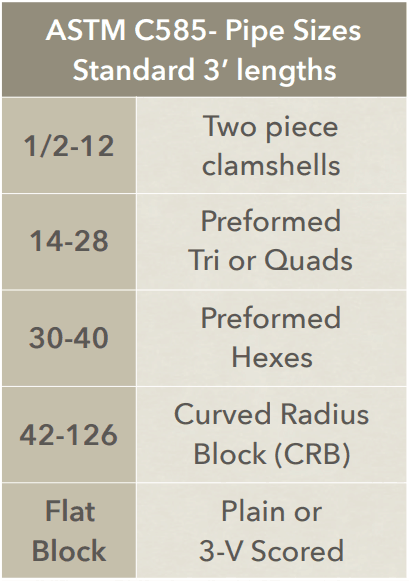

BECX-12 is a filter pressed, high-temperature calcium silicate (calsil) pipe and block insulation manufactured by BEC Industrial (Shanghai) Co.,Ltd, imported exclusively by Thermal Pipe Shields Inc. and sold through their nationwide network of distribution partner companies.

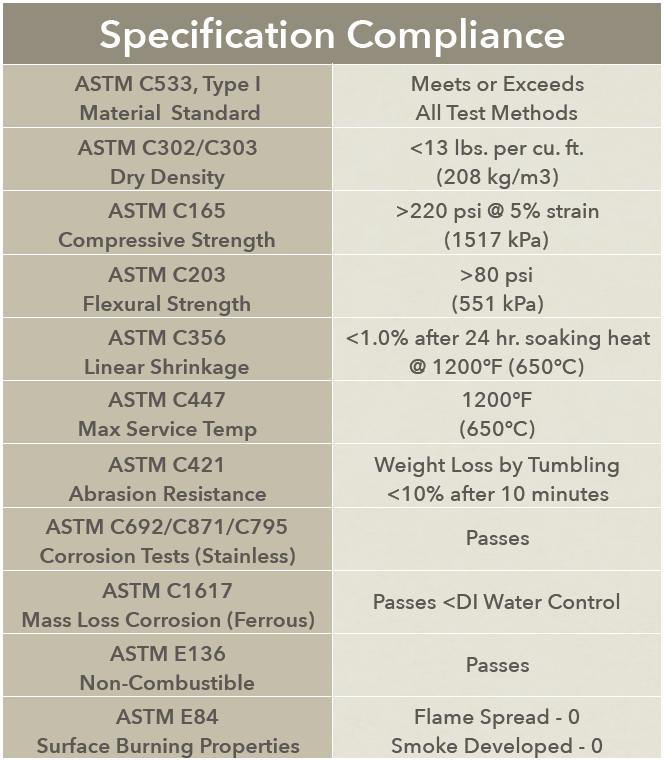

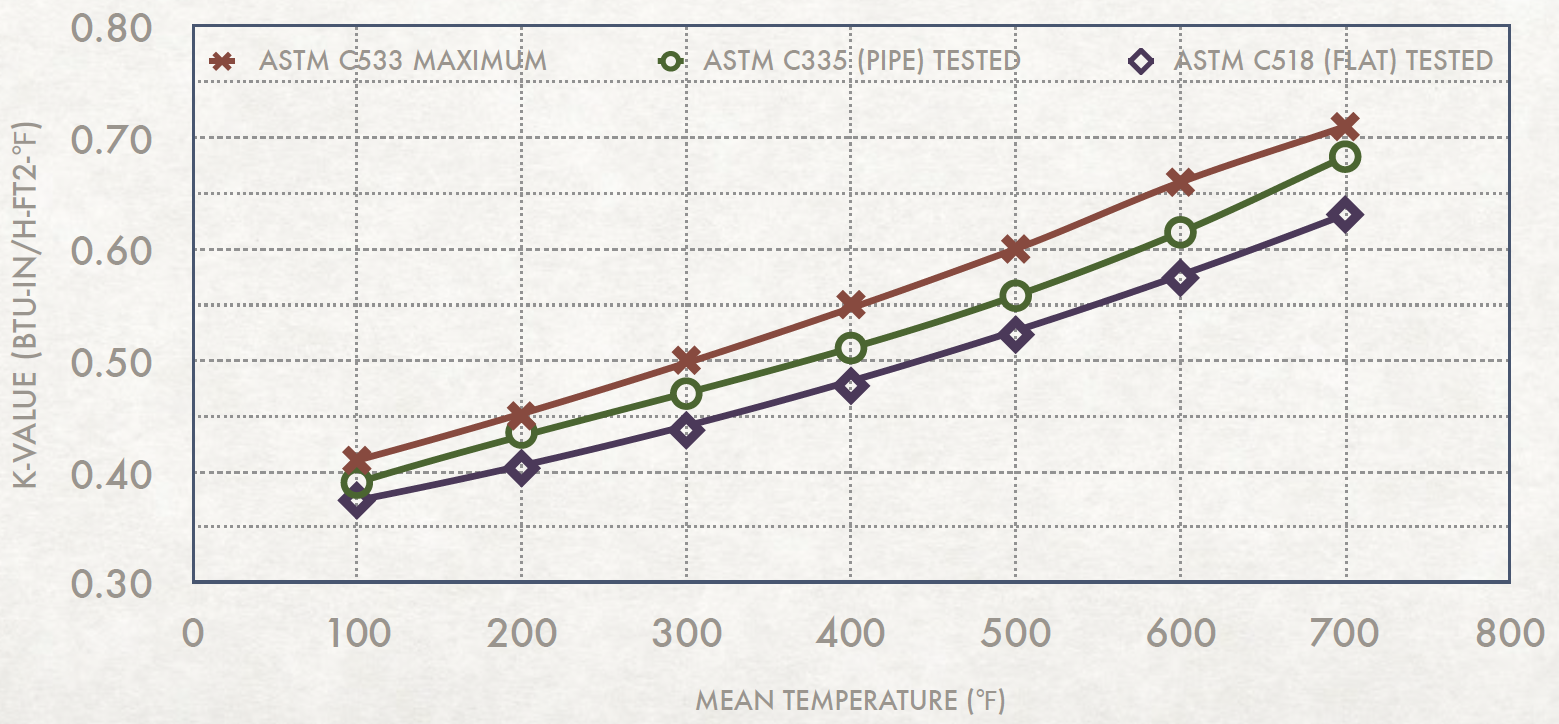

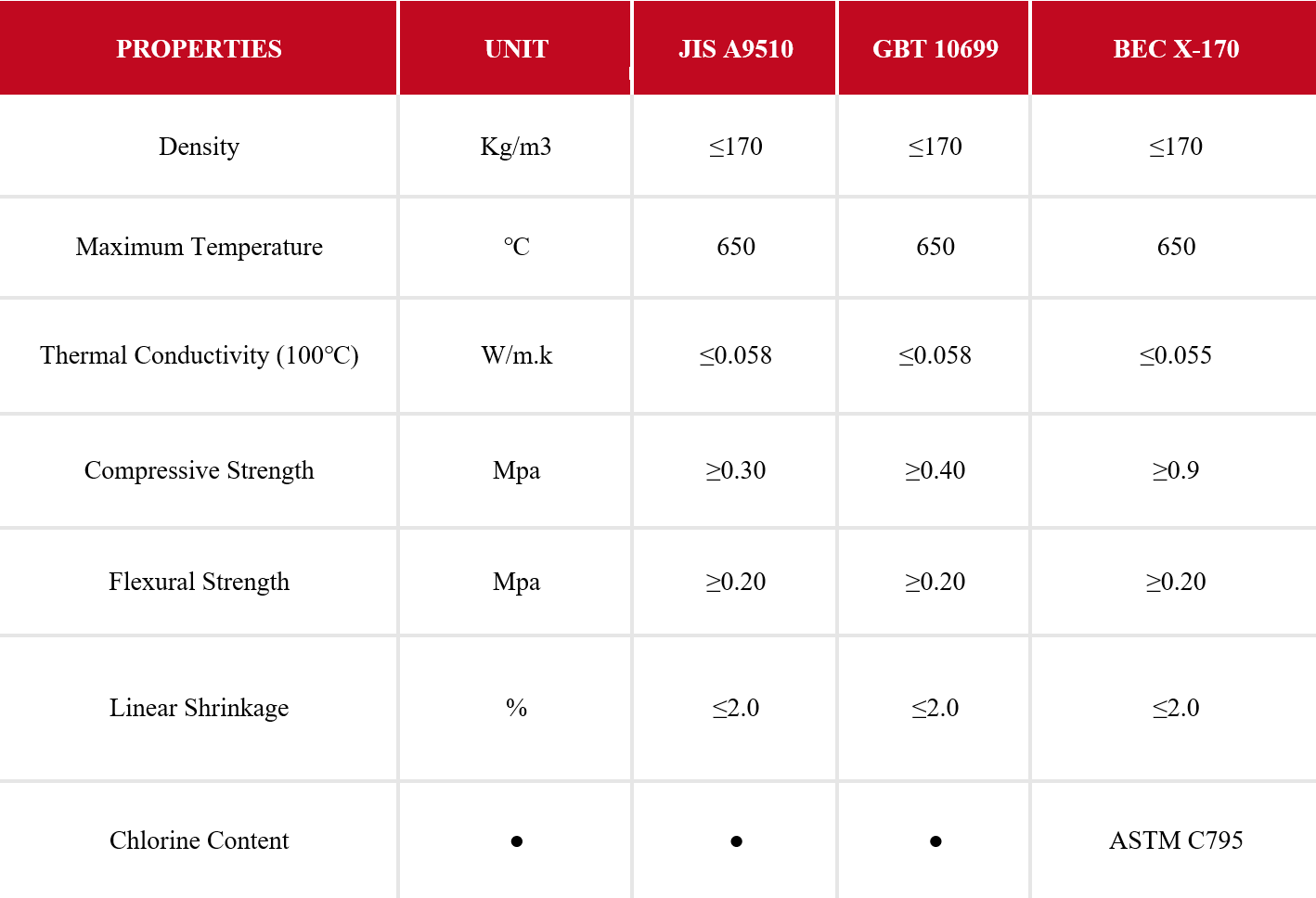

Third party verified to meet or exceed all physical property requirements in accordance with ASTM C533 Type I.

Engineered to protect industrial piping and equipment operating continuously at temperatures up to 1200℉ (650℃).

Contains integral inorganic silicate chemistry to inhibit corrosion under insulation (CUI).

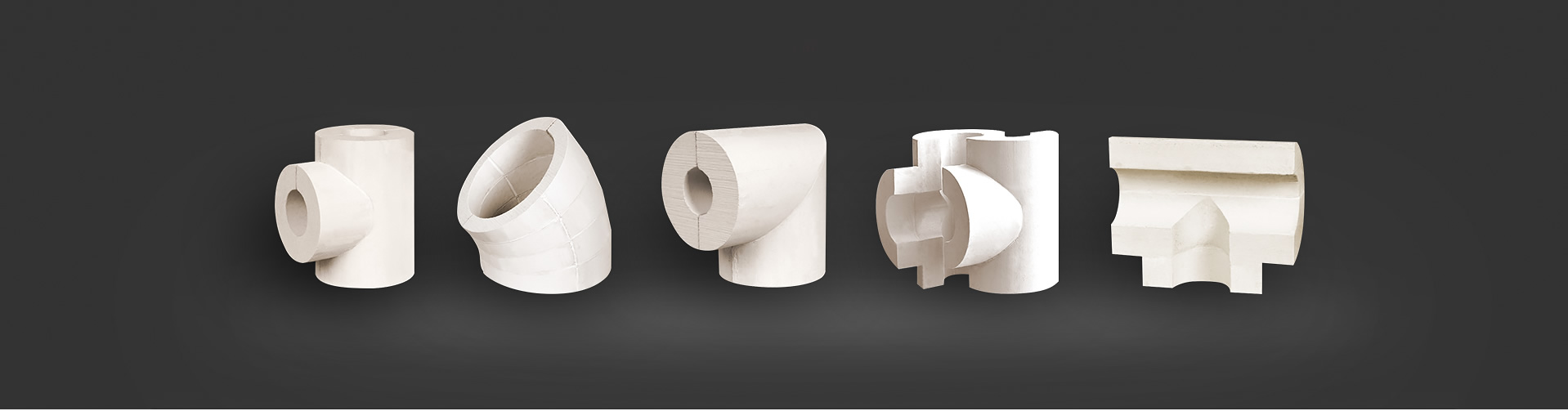

Size configurations specifically engineered to reduce lead times, increase installation efficiency with lighter, less bulky pieces,maximize packed container volumes to reduce shipping costs and reduce footprint required in construction lay down yards.

Wesupply this super light density ( below 170kg/M3 ) - X-170 calcium silicate product which meets or exceeds the Japanese Standard (JISA 9510-2-170) This material has high strength, stable properties, can provide better heat insulation effect and meet client's higher requirements.

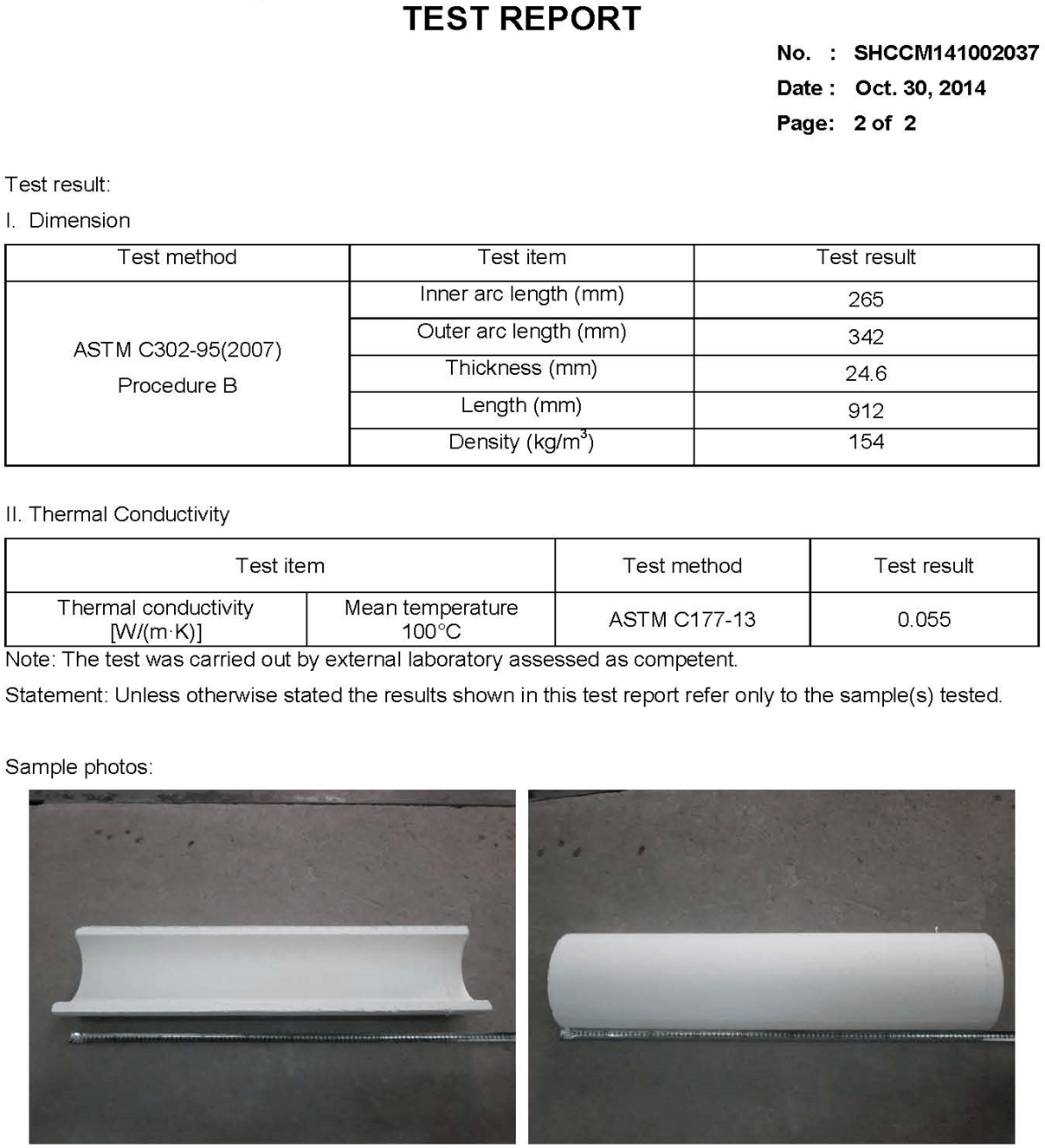

We also get the good k factor 0.055 under 100℃ with SGS test.

The average density can be realized at 150kg/m3(±10%).

We now bring this good material for customers from overseas market (not selling to USA/Canada )

It's applicable to equipment and pipeline facilities in petroleum refinery, chemical industry, hydroelectricity, nuclear power, thermal power and city heat supply network.

CONTACT US

5050 Longwu Road,MingHang,Shanghai,China

0086 21-64500049 0086 15366599305 0086 15802119398

0086 21-64500049

shjzjm@vip.163.com

Copyright © 2017, BEC Industrial(Shanghai)Co.,Ltd